Mister nozzles are small devices used to emit a fine spray of water or other liquids. They are common components in humidifiers, garden misting systems, industrial cooling systems, and more. Over time, mineral deposits and sediment can build up inside mister nozzles and clog the tiny openings that allow the liquid to spray out. A clogged mister nozzle causes uneven, weakened, or no spray at all.

Fortunately, cleaning and unclogging a mister nozzle is usually a simple process. In this comprehensive guide, as a professional Nebeldüsen manufacturer, we’ll cover everything you need to know to get your nozzle spraying like new again.

What Causes Mister Nozzles to Clog Up?

Mister nozzles clog up over time due to a natural buildup of mineral deposits from water and other liquids flowing through the mechanism.

Hard water is the number one cause of clogged nozzles. Hard water contains a high amount of dissolved minerals like calcium, magnesium, and silica. As hard water flows through the nozzle, these mineral particles accumulate along the tiny openings and eventually obstruct the flow of liquid.

Other common causes of clogged mister nozzles include:

- Sediment or dirt in the water source

- Chemical residues from cleaning solutions

- Mold, algae, and bacterial growth

- Ink, dyes, or other additives in the liquid

The smaller the nozzle openings, the faster sediment and minerals will obstruct liquid flow. Misting nozzles with very fine openings of 0.008 inches or less are especially prone to clogging issues over time.

Preventing Clogged Mister Nozzles

While periodic clogging of mister nozzles is inevitable in most applications, there are a few things you can do to reduce buildup and extend the usable life of your nozzles:

Install a Water Filtration System

Filtering out sediment and minerals from your mister system’s water source is the best way to prevent nozzles from clogging. Multi-stage filtration using sediment filters and a water softener will dramatically slow mineral accumulation in nozzles.

Flush the System Regularly

Manually flushing clean water through the system on a regular basis helps rinse out sediment before it can fully clog nozzle openings. Flushing monthly or quarterly is recommended.

Use Nozzle-Safe Additives

If your mister system contains anything other than plain water, use additive products that are specifically formulated to be safe for long-term use in nozzles. Avoid dyes, inks, and cleaning agents that can leave residue.

Replace Nozzles Periodically

No matter how well maintained, mister nozzles do wear out over time. As a general rule of thumb, replace nozzles at least once a year to maintain optimal spray performance.

How to Unclog Mister Nozzles?

If your mister nozzle has already become clogged, here are the most effective methods to clear the blockage and get it working properly again:

1. Manual Cleaning

The first method to attempt involves manually scrubbing the nozzle openings clear.

Materials Needed:

- Clean toothbrush

- Vinegar

- Franzbranntwein

- Can of compressed air (optional)

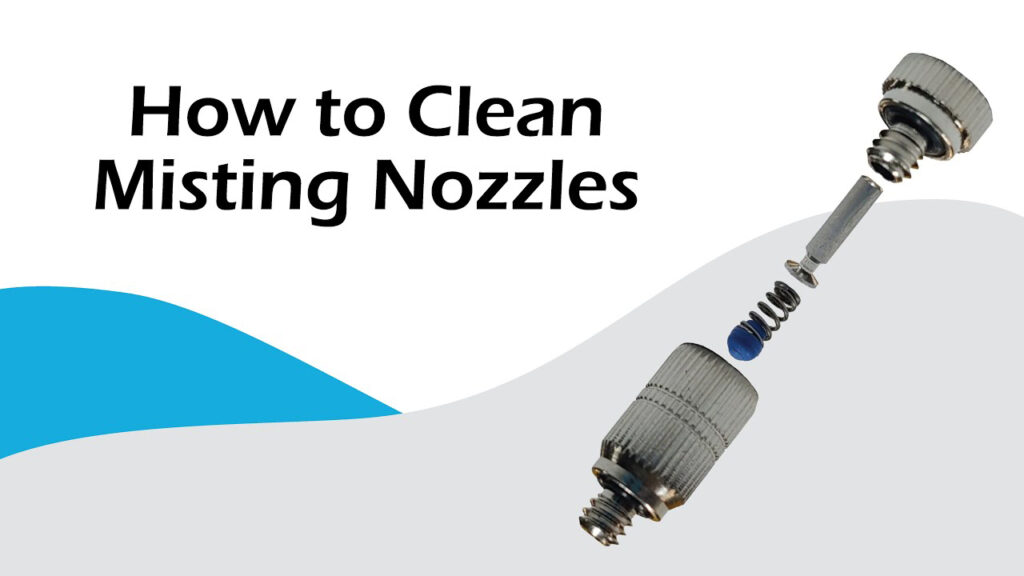

Step 1: Disconnect the nozzle from your mister system and disassemble any parts to expose the nozzle openings and channels.

Step 2: Scrub the nozzle openings using an old but clean toothbrush saturated with full-strength white vinegar. Scrub vigorously for 2-3 minutes.

Step 3: Repeat the scrubbing process using 70% isopropyl rubbing alcohol instead of vinegar.

Step 4: Rinse the nozzle under running water. If available, use canned compressed air to forcefully blow out any remaining obstructions.

The acids in vinegar will help dissolve mineral deposits, while the alcohol scrubs away any remaining gunk. Compressed air is great for stubborn sediments caught in nozzle channels.

2. Vinegar Soak

For heavily calcified nozzles, a more aggressive chemical cleaning is required:

Items Needed:

- Weißer Essig

- Plastic or glass container

- Deionized or distilled water

Step 1: Remove any o-rings or non-metal components from the nozzle assembly. O-rings can degrade if exposed to acids.

Step 2: Prepare a soak solution of 1 part white vinegar to 3 parts deionized or distilled water.

Step 3: Place nozzle in vineagar solution bath for 8-12 hours. Use a taller narrow container to fully submerge nozzle body.

Step 4: After soak time is complete, thoroughly rinse nozzle in deionized or distilled water bath.

The longer vinegar soak loosens thick mineral deposits by chemically reacting with the calcium carbonate compounds. Just be sure to rinse thoroughly after cleaning to remove all vinegar residue.

3. Ultrasonic Cleaning

Industrial-grade ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles that forcefully scrub away even the most stubborn deposits inside small crevices like nozzle openings.

Ultrasonic cleaning is the most reliable method to fully restore a severely clogged nozzle to like-new condition. However ultrasonic systems are expensive equipment best suited for commercial facilities rather than average homeowners. Companies specializing in cleaning industrial machine parts may offer ultrasonic services for a modest fee.

4. Replace Nozzle

If none of the cleaning methods are successful at unclogging your nozzle, it may be too far gone and simply need replacing.

For water misting systems used in home humidification, garden misters, or light commercial applications, replacement nozzles are an inexpensive fix readily available from most hydroponics stores or online retailers.

Industrial facilities with more complex liquid spraying systems outfitted with precision stainless steel nozzles should consult a process engineer regarding replacement nozzle specifications and installation requirements.

While throwing out a hopelessly clogged nozzle isn’t as satisfying as restoring it to working order, starting fresh with a new nozzle is sometimes the smartest option when dealing with very fine openings under 0.02 inches prone to blockages.

Schlussfolgerung

Mister nozzles provide the vital role of atomizing pressurized liquids into ultra-fine sprays and mists.

But over months or years of continuous use, normal mineral deposits in the water source will accumulate inside the nozzle openings and obstruct flow. Following the cleaning methods detailed in this guide, most basic nozzles found in home humidifiers, garden misters and light commercial systems can be fully restored to optimal performance.

For heavy industrial cooling or process spraying applications, always consult engineering guidance regarding appropriate maintenance procedures and replacement specifications to avoid damage or improper servicing.

Implementing good maintenance practices such as regular system flushing combined with periodic nozzle replacement is key for keeping any mister system operating reliably.