Our Nozzle Products

Explore high-quality industrial nozzles and discover a wide range of nozzle products tailored for precision, efficiency, and durability. Ideal for various industries, our collection ensures optimal performance for spraying, coating, and cleaning applications.

The full cone nozzle is the most commonly used nozzle type in the industry. The liquid is sprayed out in a cone and can be used for cleaning, coating, cooling, disinfection and other applications.

The flat fan nozzle has high strength, long life, large pressure adaptability, not easy to be blocked, uniform water distribution, corrosion resistance, and has a wide range of versatility in various application fields.

Hollow Cone Nozzles

The spray form of the hollow cone nozzle is a cone-shaped hollow ring. The flow direction of the water before entering the hollow cone nozzle is along the axis. The particle size of the atomization is small and it is not easy to be blocked. It is mainly used for dust removal, air humidification, and product removal.

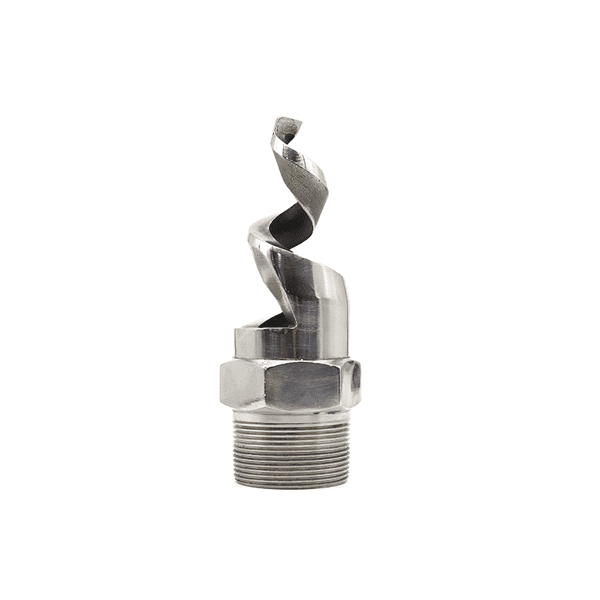

Spiral nozzle has an unblocked straight-through flow channel design without an inner core, which can make the liquid reach the maximum flow rate on a pipe of a given size. There are two spray modes, solid cone and hollow cone, with high efficiency and large spray angle, Anti-clogging.

Tank cleaning is an important process in many industrial applications. Nozzles can help maximize the efficiency of cleaning applications by ensuring the correct distribution of cleaning media and/or maximizing the effect of the available flow rate/pressure in the system.

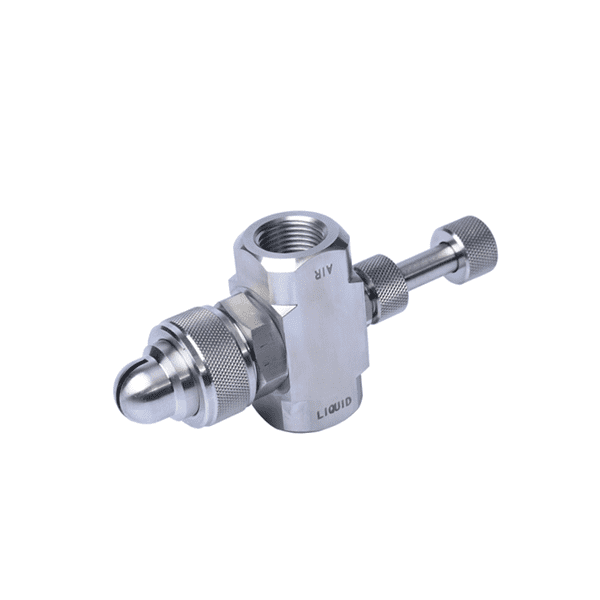

Air atomizing nozzle is a device that generates mist by air flow and liquid flow. The internal structure design can make the liquid and gas evenly mixed. By increasing the gas pressure or reducing the liquid pressure, a finer droplet spray can be obtained, which leads to a relatively small spray. High gas flow rate than liquid flow rate.

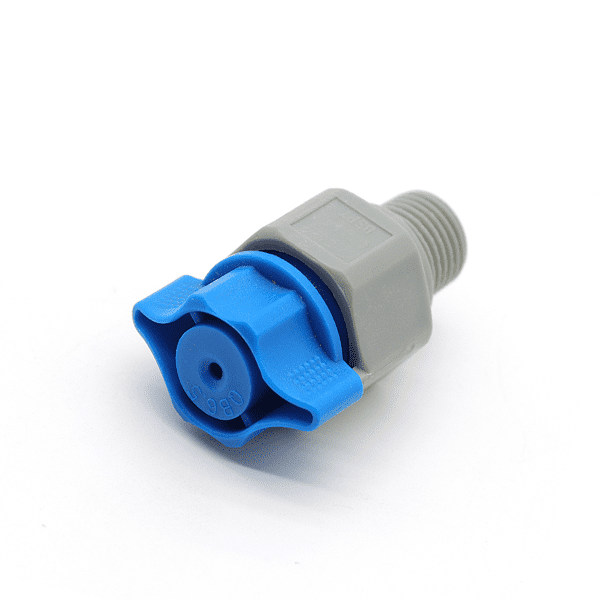

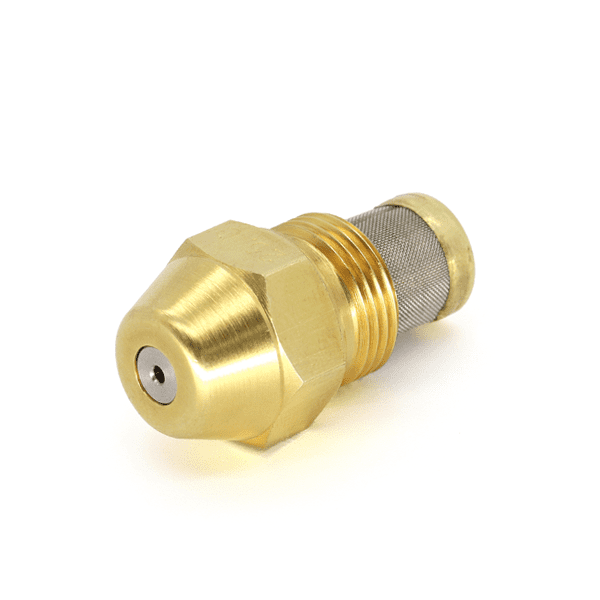

Misting nozzle can produce a fine atomization effect, the spray angle is from 45-90 degrees, and the atomized particle diameter is 10~50um. The nozzle is embedded with stainless steel nozzle core and stainless steel guide vane, and contains a drip-proof device. The liquid is 20kg -120kg water pressure, high-speed flow, a centrifugal vortex is formed in the guide vane, and very fine hollow fog particles are ejected from the nozzle hole.

PVDF is a high-hard material with high mechanical strength, abrasion resistance, impact resistance, and excellent chemical resistance. Wide selection range, long service life, suitable for most commonly used pipelines, and provide different injection flow rates and angles to meet various needs.

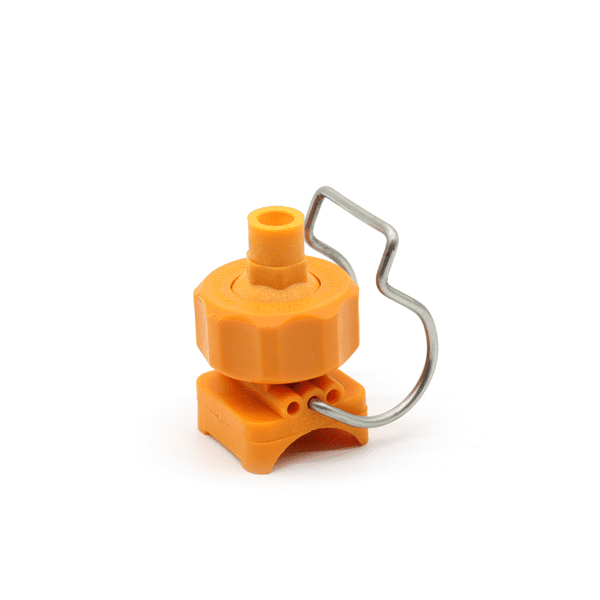

Clamp nozzle is composed of a base, a cap, a sealing ring, a spring clip, and a nozzle. This combined nozzle system can provide three different spray modes: fan, hollow cone, and solid cone. Through the combination of threaded ball, quick release ball and various common traditional nozzles, the nozzle series of adjustable spherical nozzles can be further expanded to meet diverse application requirements.

Nozzles For Paper Industry

Paper nozzles can be used to cut the edges of the paper. It has the characteristics of precise and clean edge trimming. It can form a linear liquid column flow under different pressure conditions and can withstand pressures up to 140 bar. Paper nozzle material is made of 316 stainless steel or High alumina ceramics.

Oil Burner nozzle is a special nozzle for atomizing fuel, which can produce hollow and solid spray shapes. Generally, there are several spray angles of 30, 45, 60, and 80 degrees. When studying its flow and angle parameters for this type of nozzle, its viscosity and density are generally considered. It has small size, simple structure and low manufacturing cost.

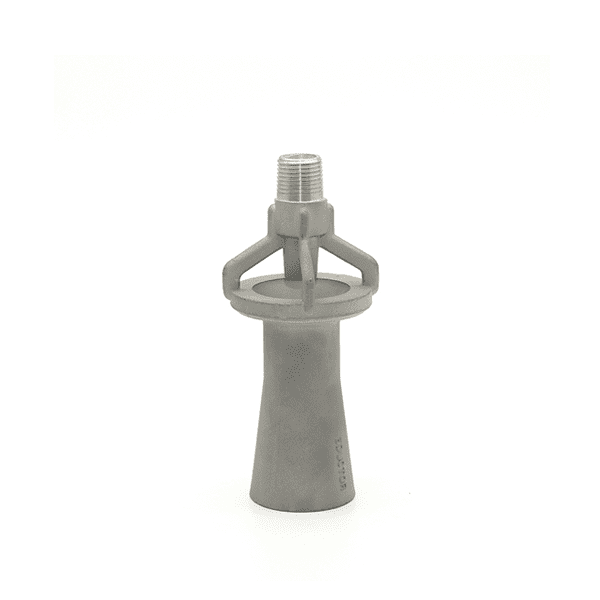

Mixing Eductor

Under the action of pump pressure, the liquid enters the mixed flow nozzle and achieves high-speed movement. Through the fluid momentum exchange, a low-pressure area is formed around the guide port. Due to the pressure difference in the area and the hydraulic momentum acting on the attracted liquid, the high-speed working jet and the attracted fluid are made. Together with 1:4 fluid delivery into the mixing and diffusion section and sprayed out to achieve the solution without air mixing and stirring.

ABOUT US

Reliable Nozzles Manufacturer

Dongguan Melinco Precision Technology Co., Ltd. is located in Dongguan City, Guangdong Province, which is known as the “World Factory”. We are the leading nozzle manufacturer in China and have 15 years of experience in producing nozzle parts. We provide standard and custom-designed spray solutions and spray nozzles for various industries and applications. Our products line include spiral nozzles, full cone nozzles, hollow cone nozzles, fine atomization nozzles, ultrasonic nozzles, flat fan nozzles, clamp nozzles, mixed flow nozzles, high-pressure water mist fire nozzles, oil burner nozzles, tank cleaning nozzles, etc.

Our Nozzles Application

Our nozzles are designed to meet diverse industrial needs, offering precision and efficiency across various applications. Below are some of the key areas where our nozzles excel:

Fire Protection

Our nozzles provide reliable and effective fire suppression solutions, ensuring safety in residential, commercial, and industrial settings.

Coating

Achieve uniform coverage with our nozzles, ideal for applying coatings in automotive, aerospace, and manufacturing industries.

Dust Control

Effectively manage dust in mining, construction, and other environments with our specialized dust control nozzles.

Drying / Blow-off

Our nozzles offer efficient drying and blow-off solutions, suitable for removing water or debris in manufacturing processes.

Lubrication

Ensure precise lubrication in machinery and equipment, reducing wear and tear with our high-performance nozzles.

Agricultural Irrigation

Optimize water usage in agricultural fields with our irrigation nozzles, designed for maximum coverage and efficiency.

Cleaning

From industrial to food processing facilities, our cleaning nozzles provide powerful and thorough cleaning capabilities.

Industrial Fuel

Our nozzles are engineered for the controlled delivery of industrial fuels, enhancing operational efficiency and safety.

Food Safety

Maintain hygiene standards with our food-safe nozzles, perfect for applications in food and beverage processing.

Gas Cooling & Conditioning

Our nozzles offer effective solutions for gas cooling and conditioning, improving air quality and system performance.

Spray Drying

Achieve consistent spray drying results in chemical, pharmaceutical, and food industries with our precision-engineered nozzles.

Humidification

Our nozzles are designed for effective humidification in various environments, helping to maintain optimal humidity levels in industrial, agricultural, and commercial settings.

Industries We Serve

Chemical Industry

We provide specialized nozzles for precise chemical processing and handling, enhancing safety and efficiency in production.

Mine Development Industry

Our nozzles are used in dust suppression, ore washing, and other mining applications, contributing to safer and more efficient operations.

Paper Industry

Optimize paper production processes with our nozzles, which are used for coating, cleaning, and humidification in paper mills.

Agriculture

Our irrigation nozzles help maximize crop yield and water conservation, supporting sustainable agricultural practices.

Food Production Industry

We offer nozzles designed for hygiene-critical processes, ensuring food safety and quality in production lines.

Pharmaceutical Industry

Our nozzles are engineered for precision in pharmaceutical manufacturing, from coating to cleaning processes.

Automotive Industry

Enhance painting, cleaning, and cooling applications in automotive manufacturing with our high-performance nozzles.

Cleaning Industry

Our versatile nozzles are used in a variety of cleaning applications, providing effective solutions for both industrial and commercial cleaning needs.

Steel Industry

In the steel industry, our nozzles are essential for cooling, descaling, and other critical processes that require precision and durability.

Shipbuilding Industry

We deliver robust nozzle solutions for surface preparation, cleaning, and coating applications in shipbuilding.

Desulfurization Industry

Our nozzles play a crucial role in flue gas desulfurization processes, helping to reduce emissions and meet environmental regulations.

Why Choose Us as Nozzles Supplier

Professional industry spray nozzle with over 15 years of experience

Complete QC system and strong after-sales concept.

Professional and dedicated engineering team

ISO series certification ensures product quality

Audit product quality to ensure quality