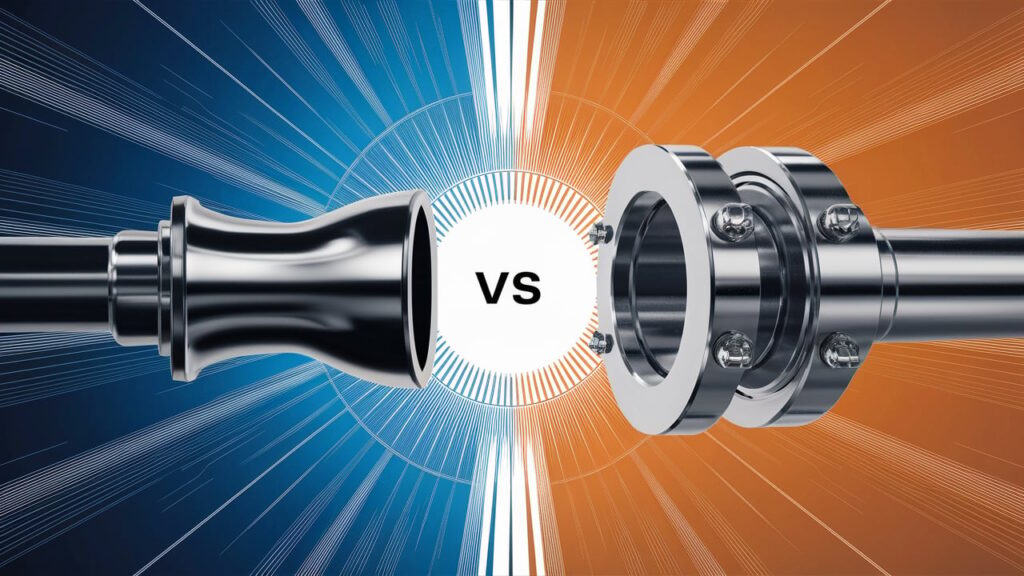

Фланцы и насадки - и те и другие можно встретить в промышленных трубопроводных системах. Но в чем же разница между форсункой и фланцем?

Как профессионал поставщик распылительных форсунокМне часто задают этот вопрос. В этом полном руководстве я расскажу все, что вам нужно знать о соплах и фланцах.

Что такое форсунка?

Начнем с насадок.

Форсунка - это короткий выступ с отверстием, обеспечивающий поступление и отвод жидкости из сосудов под давлением, резервуаров, теплообменников и другого оборудования. Форсунки способствуют соединению технологического оборудования для беспрепятственного прохождения жидкостей, газов и суспензий.

Насадки имеют стандартные размеры, определенные международными стандартами, такими как ANSI/ASME и DIN. Основными размерами, определяющими форсунку, являются:

- Размер - номинальный диаметр отверстия

- Расписание - Толщина стенки

- Проекция - расстояние, на которое сопло выступает от поверхности емкости

- Размер и тип фланца - Большинство форсунок имеют фланцы для соединения

Насадки изготавливаются из таких материалов, как углеродистая сталь, нержавеющая сталь, хромовый и никелевый сплав. Распространенными типами форсунок являются:

- Насадка с приварной горловиной - короткая цилиндрическая горловина с приваренным фланцем

- Цельное сопло - сопло и емкость изготовлены из одной детали

- Самоусиливающееся сопло - Сопло с увеличенной толщиной стенок

Теперь давайте посмотрим на фланцы.

Что такое фланец?

Фланец - это выступающий обод или воротник, используемый для крепления труб и другого оборудования с помощью болтов. Фланцы позволяют легко соединять трубы без сварки.

Ключевыми размерами, определяющими фланец, являются:

- Номинальный размер трубы

- Тип поверхности фланца - плоский, рельефный, кольцевой, шпунт и паз

- Номинальное давление - 150#, 300#, 600# и т.д. Класс вызываемого фланца

- Наружный диаметр

- Размер отверстия под болт и диаметр окружности

Фланцы соединяются с помощью прокладок для обеспечения герметичности. Распространенными типами фланцев являются:

- Сварная горловина - отверстие соответствует ID трубы

- Накладка - отверстие больше наружного диаметра трубы

- Муфтовая сварка - Резьбовое отверстие

- Нахлесточное соединение - фланец перекрывает трубу

- Слепой - цельный фланец крышки

И форсунки, и фланцы играют важную роль в проектах технологических трубопроводов. Но чем именно они отличаются?

4 ключевых различия между форсунками и фланцами

Хотя форсунки и фланцы часто работают вместе, они служат для разных целей:

1. Герметичность

Для обеспечения герметичности при соединении фланцев используются прокладки. Форсунки не требуют прокладок, вместо них герметичность обеспечивается сваркой.

2. Тип соединения

Фланцы используются для быстрого соединения одного участка трубы с другим с помощью болтов. Форсунки привариваются к сосудам или теплообменникам на постоянной основе.

3. Назначение потока

Фланцы просто соединяют - они не способствуют движению потока. Форсунки подают и выводят жидкость из технологического оборудования, например, из емкостей и резервуаров.

4. Физические атрибуты

Фланцы имеют стандартные размеры, определяемые номиналами фланцев. Размеры форсунок не стандартизированы и зависят от конкретного применения.

Понимание этих ключевых различий поможет вам оптимизировать взаимосвязь трубопроводов и оборудования.

Некоторые инженеры используют термины "фланец сопла" или "фланцевое сопло". Что означают эти гибридные термины?

Фланец форсунки и фланцевая форсунка

Некоторые типы форсунок имеют фланцы, приваренные к их концам.

Такие конфигурации стирают границы между соплом и фланцем, поэтому используются два взаимозаменяемых термина:

- Фланец форсунки

- Фланцевое сопло

Это не отдельные типы оборудования. Это просто сборки форсунок и фланцев. Наиболее распространенным типом является рельефный шея для сварки лица (RFWN) сопло.

RFWN обеспечивают простое болтовое соединение, сохраняя при этом пропускные свойства сопла. Фланец приваривается к короткой цилиндрической горловине, выступающей над поверхностью емкости.

Понимание такой тонкой терминологии, как "фланец форсунки", устраняет путаницу вокруг такого оборудования, как форсунки и фланцы.

А если вы знаете, как форсунки и фланцы работают независимо друг от друга, гибридные конфигурации становятся легко визуализируемыми.

Сейчас я отвечу на некоторые распространенные вопросы инженеров, связанные с форсунками и фланцами.

Часто задаваемые вопросы

Здесь представлены ответы на некоторые из наиболее часто задаваемых вопросов о насадках и фланцах:

Нужны ли форсунки на сосудах под давлением?

Да! Форсунки обеспечивают поступление и вытекание потока из емкости. Без форсунок внутренние части емкости не могут соединяться с другим технологическим оборудованием.

Могут ли фланцы протекать?

Да, утечки во фланцах - обычное дело, если прокладки не затянуты должным образом. Для предотвращения утечек всегда используйте контроль крутящего момента при соединении фланцевого оборудования.

Выдержит ли более высокий номинал фланца большее давление?

Да, в пределах нормы. Фланец 300# может выдерживать почти вдвое большее внутреннее давление, чем фланец 150#. Но более высокие номиналы имеют меньшие допуски по давлению.

Могут ли форсунки заменить фланцы в трубопроводах?

Нет. Поскольку они постоянно привариваются к оборудованию, форсунки не могут обеспечить съемность фланцевых соединений труб. Они служат совершенно разным целям.

Я надеюсь, что это руководство помогло объяснить разницу между соплами и фланцами в понятных терминах. Понимание того, как соединяется технологическое оборудование, жизненно важно для каждого инженера.

Сообщите мне в комментариях, если у вас есть другие вопросы по форсункам или фланцам! Я всегда рад пообщаться с вами по поводу оборудования и терминологии для технологических трубопроводов.