A standard flat fan nozzle typically operates within a pressure range of 30 to 60 pounds per square inch (psi), with the ideal range considered to be between 30 and 40 psi.

En este puesto, como profesional proveedor de boquillas pulverizadoras, I will talk about everything about the operating pressure of a flat fan nozzle.

Why Operating Pressure Matters

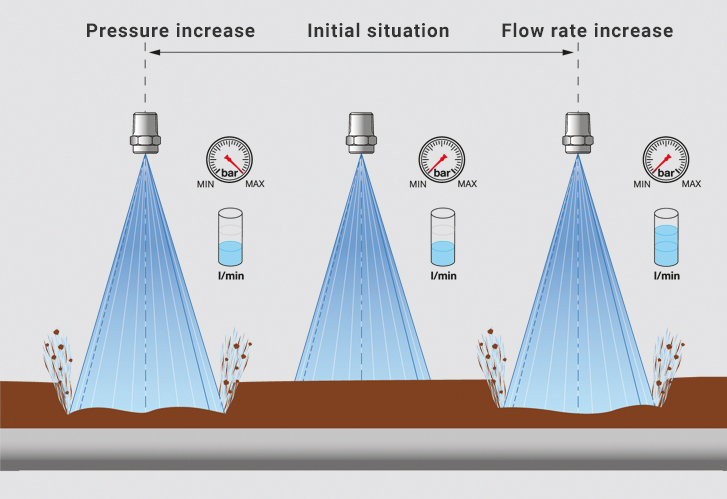

The operating pressure of a nozzle is important because it significantly impacts spray performance and quality. Key factors influenced by pressure include:

- Spray pattern – Higher pressures generally produce wider fan angles while lower pressures cause spray collapse.

- Droplet size – Higher pressures create smaller droplets while lower pressures produce larger droplets.

- Application rate – Flow rate through the nozzle increases as pressure increases.

Understanding these dynamics allows applicators to select pressures that optimize application efficacy while reducing risks like drift.

Ideal Pressure Range of a Flat Fan Nozzle

Most flat fan nozzles are designed to have a recommended operating range of 30-60 psi. Within this range they will produce consistent, uniform spray patterns and droplets.

The 30-40 psi zone is often considered the “sweet spot” where drift potential is minimized while coverage and efficacy are maximized.

Benefits of Lower Pressures

While 30-60 psi is the normal operating range, running flat fan nozzles at lower pressures has some advantages:

- Enlarges droplet size to reduce drift.

- Lowers flow rate, allowing reduced carrier volumes.

- Reduces strain on pumps and plumbing components.

When spraying herbicides, larger droplets at lower rates are often still effective for controlling weeds. This can improve efficiency.

Considerations at Low Pressures

There are a few issues to keep in mind when operating flat fan nozzles below 30 psi:

- Spray pattern collapse – Fan angles narrow at extremes, reducing coverage.

- Poor atomization – Lower liquid shear forces produce more variable droplets.

- Clogging – Larger orifices needed for equivalent flow are prone to plugging.

Nozzles may still function down to around 15 psi but performance consistency declines. Always check spray patterns when lowering pressure significantly below 30 psi.

Specialty Low Pressure Nozzles

In recent years new flat fan nozzles have been introduced that work at lower minimum pressures. Examples are the extended range and low pressure flat fan tips.

These are engineered to maintain excellent spray uniformity down to 15 psi. They produce larger drift-reducing droplets but use a pre-orifice to prevent pattern distortion.

Considerations at High Pressures

While most flat fan nozzles are rated to 60 psi, it’s best to avoid excessive pressures above 40 psi when possible. Here’s why:

- Increased drift – Higher pressures produce very small, drift-prone droplets.

- Faster wear – Thinning nozzle material erodes orifices more quickly.

- Stressing components – Excess pressure can damage pumps, lines, gaskets, etc.

If more flow is needed, switch to higher capacity nozzles rather than increasing pressure alone. This maintains droplet integrity and equipment life.

In summary, a typical flat fan nozzle will perform best around 30-40 psi based on spray quality and equipment reliability factors. Lower pressures down to 15 psi are option for some drift reduction while higher pressures above 40 psi can compromise efficacy and hardware wear. Understanding these dynamics allows matching pressures to optimal performance.

More Specific Operating Pressures

While most standard flat fan operate well in a 30-60 psi range, here is some additional context around more specific operating pressures to help determine the best settings:

15 psi

- At 15 psi, some spray pattern distortion or collapse can occur with standard flat fan nozzles. Specialized “low pressure” or “extended range” designs maintain patterns better at this pressure.

- 15 psi produces extremely coarse droplets prone to runoff, plus risks inadequate coverage and control. Only viable with systemic or contact herbicides requiring minimal coverage.

- Best for flood-type applications or specialized coarse spray where <150 micron droplets desired to limit drift.

20 psi

- Improved pattern uniformity over 15 psi on standard flat fan tips. Low pressure nozzles excel here.

- Marginal minimum pressure for insecticides/fungicides. Post-emergent contact herbicides also borderline.

- Drift potential significantly lower than higher pressures.

30 psi

- The bottom threshold for the operating range of most standard flat fan nozzles. Performance should be consistent and predictable from here up on conventional designs.

- Considered ideal for drift reduction while still maintaining efficacy.

- Good benchmark pressure for systemic herbicides, insecticides, fungicides applied to field crops.

40 psi

- Mid-point of the operating range for standard flat fans tips. Optimizes uniform distribution while moderating risks.

- Droplets are still relatively large.

- This is a common baseline pressure used by nozzle manufacturers when rating flows, spray angles, etc.

50 psi

- Approaching the higher pressures flat fan nozzles can fully handle.

- Smaller droplets pushed deeper into crop canopy with more energy.

- Higher coverage potential but also increased drift risks.

- Higher strain on spray system components.

60 psi

- The maximum recommended pressure for most conventional flat fan nozzles. Risk of premature failure escalates over 60 psi.

- Very small droplets prone to drift. Use air induction nozzles or other drift reduction measures.

- Harder pressures also impart more shear force, breaking liquid up into uneven droplets.

Key Takeaways on Pressure

There are a few key things to remember regarding flat fan nozzle pressures:

- Try to operate within an ideal range of 30-40 psi. This balances efficacy and equipment reliability.

- Standard designs function over a 30-60 psi range. Performance declines beyond these thresholds.

- Lower pressures enlarge droplets for reduced drift but can also compromise coverage at extremes.

- Higher pressures shrink droplets for better canopy penetration yet also dramatically increase drift risks.

- For optimized drift reduction and coverage, use tips specifically designed for lower operating pressures.

Matching pressures to nozzle capabilities and pesticide needs is critical to achieve success. This allows dialing in an ideal combination of application efficacy, spray quality and equipment function.